Two months "anniversary" and progress on elevator

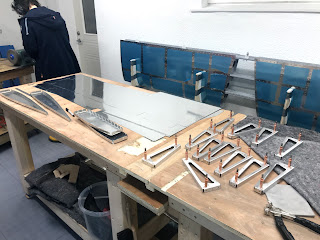

Two months has passed since starting, and approx. 160 hours spent building plus another 10-15 on workshop etc. The progress on the elevator has been good this week. Page 09-08 step 6 was completed today, but as I didn't understand how to sand/adjust the trailing edge cross section to fit the fairing, I decided to prepare the fairings in chapter 12 before proceeding. Finding and preparing all the parts. The tip ribs for both side assembled and match/final drilled. Foam blocks are used as ribs. The templates from the manual are just glued on with spray clue. First two ribs cut. Very easy with a band saw. The left elevator side has a trim tab, so the top and bottom skin has a flange that needs to be bent 90 degree so they mates together. The piano hinge for the trim tab on the elevator is drilled. I used a caliper to adjust the hinge parallel to the flange every 12-15 cm. This is the area were the electric trim motor will be installed. It will be a...